Resistance Soldering

When it comes to Resistance Soldering, no other company in the world combines the depth of knowledge with the breadth of product offerings as American Beauty.

American Beauty offer the widest selection of handpieces, electrodes and power units and back our equipment with the industry?s best warranty.

Together with American Beauty, we work hand-in-hand with customers to help them realise the benefits of resistance soldering.

What Is Resistance Soldering:

Resistance Soldering is a unique soldering process which utilizes special equipment that has been developed to provide the heat necessary to activate flux and flow solder in a safe and efficient manner with the use of resistance heat.

Thermal energy is produced by the conduction of an electrical current through a resistive material to create the resistance heat that is required. The amount of heat that is produced can be regulated by controlling the amount and type of electrical current that is being conducted along with the amount of resistance that is being encountered.

The equipment intended for this type of resistance heating is capable of producing high enough temperatures to melt and flow most solder alloys ranging from low temperature (soft) to higher temperature (hard) solders. This range also includes lead free and silver solders as well as certain types of brazing materials. Resistance heat offers a safe and efficient method of soldering and brazing that may improve the overall quality and repeatability of your soldering process while decreasing the probability of inconsistent solder joints and potential thermal damage to heat sensitive components.

How it works:

Electrical resistance (which is usually described as a materials opposition to the flow of an electric current) is used to convert electric energy into thermal energy because an electric current (I) that is being conducted through any material with resistance (R) causes the electrical energy to be converted to thermal energy at a rate of power (P) equal to:P = I2 x R

Where P is the power measured in watts, I is the current measured in amperes and R is the resistance measured in ohms.

This thermal energy is used in applications that are usually referred to as either electric heating or resistance heating and offers several advantages over other methods of generating heat. Resistance heaters have an inherent efficiency of 100% in converting electric energy into thermal energy and are used in many heating devices such as sterilizers, clothes dryers, space heaters, ovens, electric ranges, water heaters, hair dryers, coffee makers, furnaces and many others. This clean safe heat does not involve any combustion or open flames and it can be precisely controlled to create temperature uniformity within narrow operating limits. An electric heat source can be protected from overloading with the use of circuit breakers or fuses making it safe to use. The initial heat availability and response to adjustment that are made are usually very rapid.

With all of these advantages it is easy to understand why electric heating has so many uses in industrial, commercial and residential applications.

Making this type of thermal energy safe for hand held tools that are used in soldering and brazing applications requires some modification to the type of current that will be used to develop the necessary heat. By passing a standard 110-120 (or 220-240) AC line voltage through one of our specially designed, isolated step down transformers a safe, low-voltage, high-amperage, AC out-put current is developed. The transformers developed for American Beauty resistance soldering power units have been tested by an independent laboratory and are all manufactured in conformance with the applicable sections of the Standard for Safety for Class II and Class III Transformers (UL 1585, 4th Edition) and with the Standard for Isolating Transformers and Safety Isolating Transformers (IEC 742, 1st Edition).

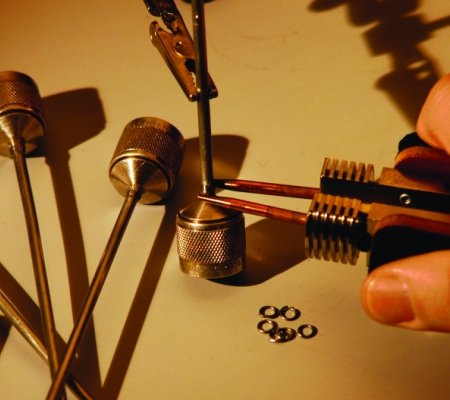

The safe low-voltage current that is developed with American Beauty resistance soldering power units can be controlled and conducted through a variety of handpieces, each of which have some form of resistive electrodes or elements in place to produce the resistance heat. Many of the electrodes that are used for resistance soldering or brazing have copper plated outer jackets in order to maintain higher conductive properties until the current reaches the tips of the electrodes directing the heat exactly where it is required for the soldering or brazing to take place. Shaping the electrode tips to closely match the contour of the surface to be heated may improve the flow of thermal energy to the intended braze or solder joint area.

Electrodes are produced in different sizes and from a variety of materials in order to meet the specific requirements of a wide range of applications. Some materials allow the electrodes to be bent giving access to areas that might otherwise be inaccessible. Others may be brittle but can hold up to significantly higher temperatures without melting away.

Uses:

Because of the intense level of thermal energy that is made available when utilizing resistance heating equipment, you will be able to perform a wide variety of soldering and brazing applications where very high temperatures might be required.

By matching the appropriate handpiece and power unit to the intended application, your resistance heating equipment may be used for applications ranging from soldering components on a circuit board to brazing 3/4″ copper pipe or sweat soldering 3″ diameter thin wall copper tubing.

You might be interested to know that American Beauty resistance soldering equipment can also be used for thermal wire stripping applications, simply by changing to the type of handpieces that are required for this task. This includes thermal stripping of wires that have high temperature (PTFE type) insulations.

Advantages:

You will experience several benefits when using Resistance Soldering over the many other soldering methods that are currently available. These benefits will include, but are not limited to the following:

- Quality: Because a higher level of heat is available directly where it is needed, you will find that fewer cold solder joints are produced. The flux being used will be more thoroughly activated allowing for better wetting and there will be less chance of getting solder into unwanted areas.

- Efficiency: A more direct and higher level of heat means faster soldering takes place, allowing for less heat dissipation into the work piece. This means you will experience faster cooling and fewer rejects caused by damage to heat sensitive components. The amounts of solder and flux needed will decrease and solder times can be cut by more than half.

- Repeatability: More consistent solder joints will be no problem because of the direct heating approach. By properly setting the Power Units out-put and performing consistent time cycling you will find that your solder joints are much more uniform. Being able to rely more on the soldering equipment for consistency, means easier training of your operators.

- Safety: There is no chance of an operator being shocked by hazardous voltage, produced by the Power Unit or Handpiece; because the current being produced is very low AC voltage. Because heat is manufactured by Resistance Soldering equipment only during the actual soldering application, there are no hot tools left idling in the work area to be concerned about and no open flames. Because of the ability to solder more rapidly there is less accumulated heat in the work and tools, allowing for safer handling.

- Savings: Improved quality will mean a lower rejection rate and less rework. Greater efficiency will lower your overall operating and utility costs, and less solder and flux will be required. Consistent repeatability and ease of use reduces the amount of time required and the costs associated with the training of new operators. Increased safety helps to reduce the likelihood of incurred costs associated with accidents or injuries.

- Availability You will find that our extensive line of Resistance Soldering equipment is available through many authorized American Beauty distributors across North America and around the world.

How to videos can be found on our video page here (this link will open a new tab)

Reviews

There are no reviews yet.